Choosing a commercial-grade grow room dehumidifier requires a more engineering-oriented approach than consumer units because commercial spaces have higher moisture loads, continuous operation, integration with HVAC controls, and serviceability requirements. Below is a structured process you can follow to select a proper unit for a commercial grow environment.

Grow Space Volume

Compute the room’s gross air volume:

Length × Width × Height = Cubic Feet (CF)

Commercial grow facilities can range from hundreds to tens of thousands of cubic feet — sizing scales non-linearly with volume.

Commercial facilities typically manage RH more tightly:

Vegetative: 55–70% RH

Flowering: 40–50% RH

Cloning/Propagation: 60–80% RH

Set your design setpoint based on your most stringent requirement (typically flowering) because your dehumidifier must maintain that reliably.

Commercial calculation is load-based, not just room size:

Sources of Moisture

Transpiration from plants (primary source)

Irrigation evaporation

Ventilation with outdoor air

Infiltration / leaks

Evaporative coolers or foggers

Plant Transpiration

Transpiration depends on:

Light intensity

Temperature

VPD (Vapor Pressure Deficit)

Plant species and density

Professional growers often estimate:

0.3–0.7 lbs of water per gallon of plant canopy per hour in full flower

You can also derive moisture load from:

Irrigation schedules

Air exchange rates

Latent heat load from HVAC design

Note: Commercial engineers typically use psychrometric analysis — load in lbs of water per hour (lb/hr) or kg/hr, not just pints/day.

Commercial dehumidifiers are sized in lb/day or kg/day moisture removal at specific conditions, or in HVAC terms latent capacity in BTU/hr.

Conversion reference:

1 pound of water ≈ 1 pint (US)

1 lb/hr moisture removal ≈ 24 pints/day

A commercial load might be tens or hundreds of pounds per day.

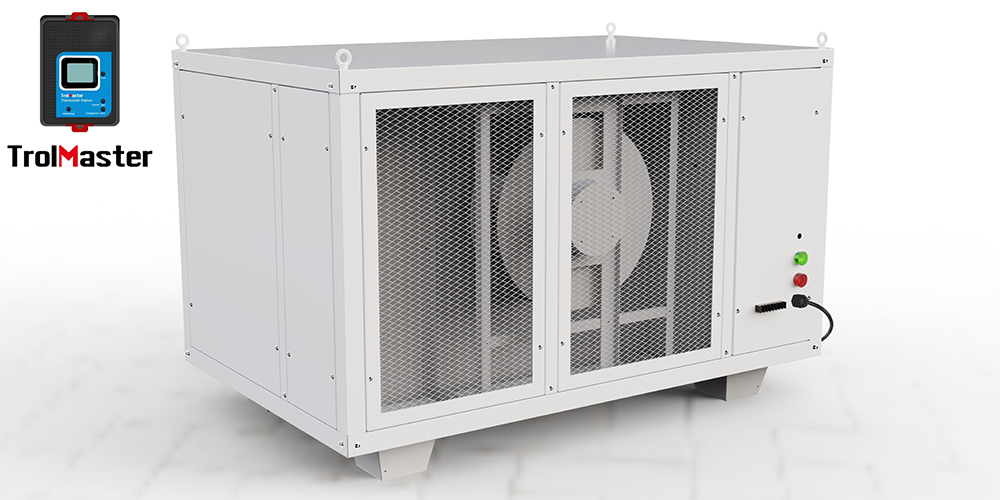

Compressor-Based (Refrigerant) Units

Best for warm and humid spaces

High capacity at typical grow temps (~70–85°F)

Can be packaged or modular

Use a professional greenhouse dehumidifier to remove moisture

Excel at low dew point and low temperature

Ideal when you need very low RH (<40%) or operate cooler

Commercial dehumidifiers should integrate with:

Building automation systems (BAS)

Environmental controllers (ECs)

HVAC latent and sensible loads

Fresh air ventilation and exhaust heat recovery

Control Features to Require

Analog/Digital I/O for external setpoints

Modbus / BACnet / other protocols

Remote humidistat probes (not at unit intake)

Continuous drain with proper plumbing

Alarms and fault reporting

Commercial installations rarely rely on a single unit:

N+1 redundancy: one extra unit beyond required capacity

Staged units: modulate capacity to meet variable loads

Load sharing across rooms or zones

This ensures uptime and fewer crop interruptions.

Capacity alone is not enough; you also need effective airflow:

Dehumidifier CFM must cycle room air 6–12×/hr (typical guideline)

Ensure no dead spots – often use ducted return/airwash configuration

Commercial units need:

Easy access to filters, coils, and blowers

Serviceable parts

Local technical support

Diagnostic interfaces

Ease of maintenance reduces downtime and cost.

Room: 30' × 50' × 12' → 18,000 CF

Plants: Full flower, high transpiration

Ventilation: 20% outside air

Irrigation evap load: significant

Engineer calculates:

Moisture load = 15 lb/hr (360 pints/day)

Choose unit(s) with capacity > 360 pints/day at design conditions

Control integration: Tie into BAS with remote sensors

Prev:none